It's no secret that the stock horn leaves a lot to be desired. The one on my '73 gave up the ghost, so I figured why not try and mount nice loud air horn. I found the Stebel Nautilus Compact Motorcycle Air Horn for about $35 on Amazon and it looked to be the perfect thing.

I was interested in trying to mount this in the stock position and managed to get some of the way there. It's possible to detach the horn from the pump - it's held by a clip moulded into the plastic horn section. By separating the two, you can mount the compressor in the stock location. I mounted the horn on the frame just behind the oil tank.

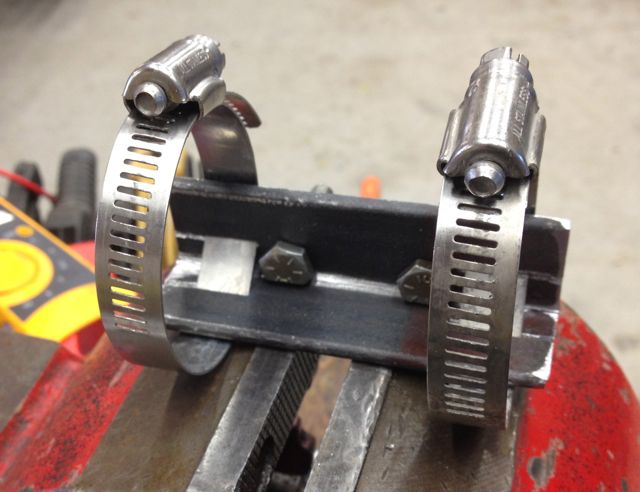

I started by fabricating a bracket out of some 1/8" by 1" angle and a couple of hose clamps. It seems to work just about right.

Here's my mock up test fit before I pulled apart my bike (I happened to have a '75 battery tray around).

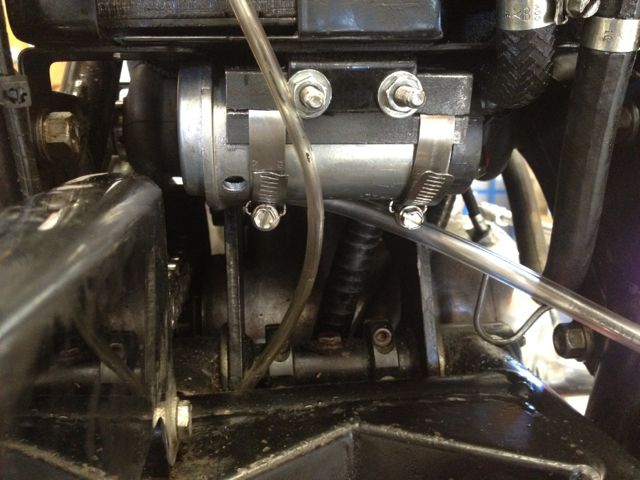

After I pulled apart the bike I realized I needed to saw off the stock pump mount for clearance with the cradle:

Here it is mounted! That hole just to the left of the leftmost hose clamp is the air intake for the pump. I thought by having it pointed downward would keep some of the junk out.

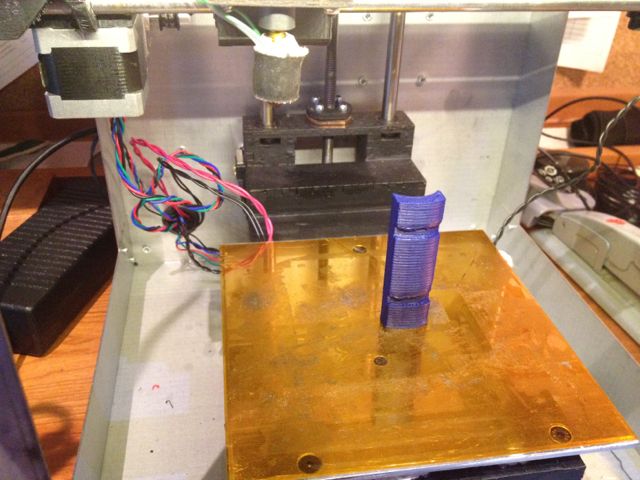

I then had to figure out a way to mount the plastic part. I got to use my handy new Soldidoodle 2 3D printer to make a bit of plastic to allow the horn to be strapped to the frame tube. I just love this thing. In about 30 mins I was able to glue this to the horn and was ready to mount. If anyone wants the STL file for this here it is - frameadptr.stl

First I "lightly" threaded the air intake port for 1/8" NPT and threaded in a 1/4" hose barb. I locked this in with some JB Weld.

And here it is mounted on the frame. I wanted the openings downward to keep water out so I mounted it on the right side. It could have gone on the left (and would have been a bit better as this obscures the oil tank lines, but you don't normally need to get to them, so I'm OK with this location).

I upgraded this Commando to 12v neg ground and had no issues with the pump. I did check the ground lead for continuity against the case and found none - which means it should work OK with a positive ground system. You need a strong battery to turn the pump fast enough to get the horn to fire - mine was low and it didn't work at first. Hooking up the battery charger or getting the bike running fixed it. All in all it went pretty smoothly. Pulling off the rear fender was a bit of a pain, but no worse than any other standard Norton task...