C30 - Assembling Right (Timing side) of Engine

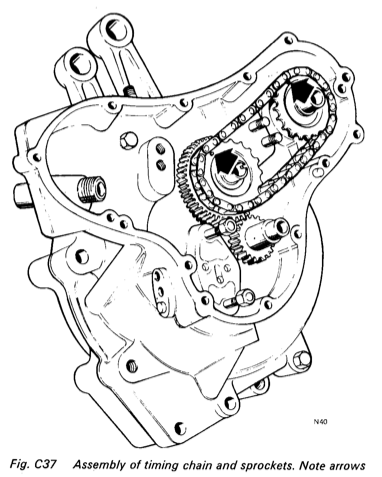

This assumes the crankcases are assembled as in Section 29. Mount the crankcases securely. Now we can put the cam chain, sprockets and oil pump.

1) Fit the oil sealing disc over the timing side crankshaft - lip outwards.

2) Next comes the cut-away backing washer

3) Put the woodruff key into the crankcase then the crankshaft pinion, chamfered teeth and timing mark outwards. Make sure it's fully seated home - you may need to tap it.

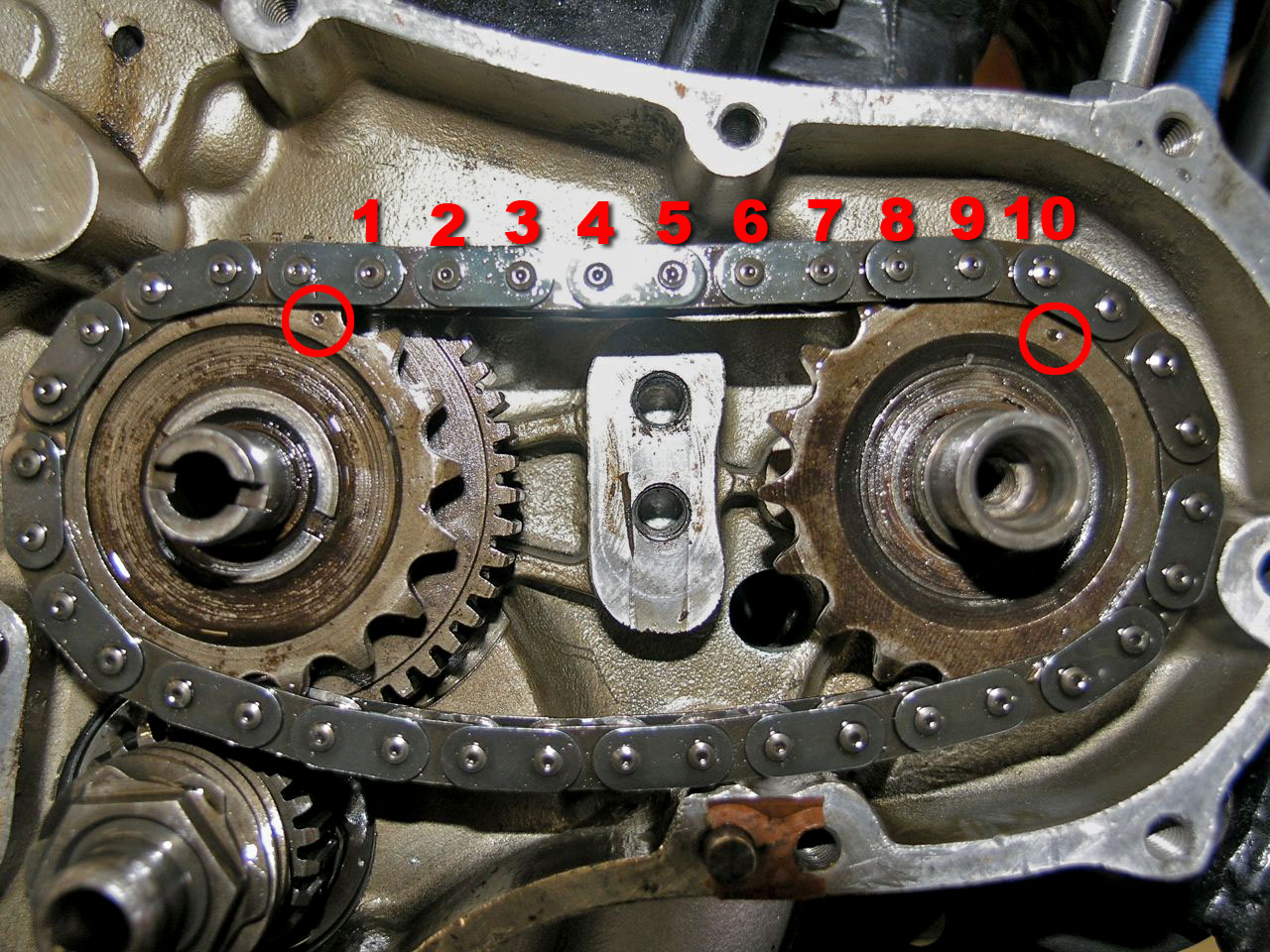

4) Turn the crank to TDC so the timing pinion mark is up

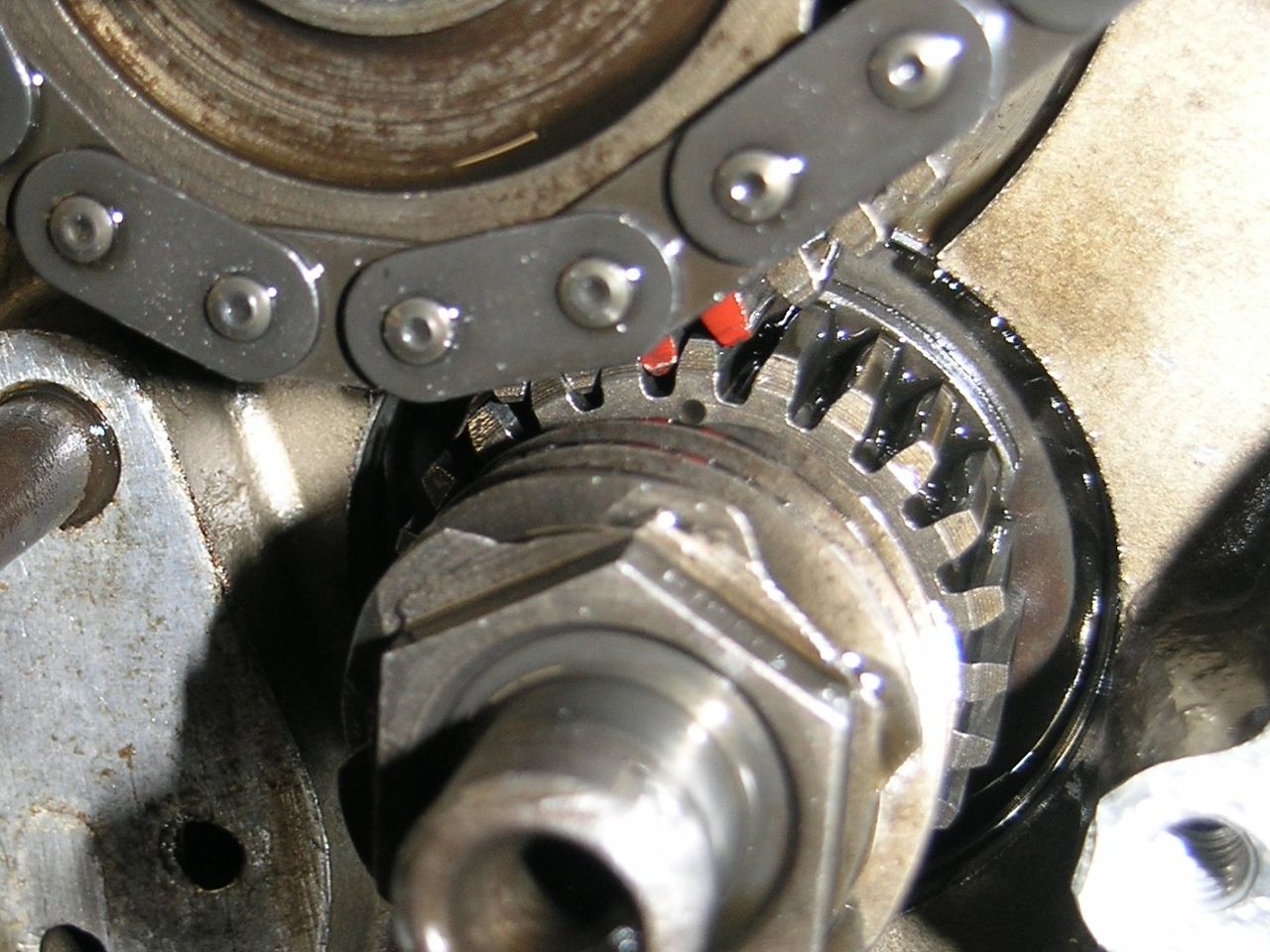

5) Take the intermediate gear, cam sprocket and chain as a unit and mount. The timing marks must be 10 rollers apart on the chain for correct cam timing.

6) Locate the camshaft sprocket and intermediate gear and sprocket in posiiton, mating up the marked space between the teeth on the intermediate gear (painted red) with the marked tooth on the timing pinion (has dimple). There should be a paint mark on the intermediate gear to help.

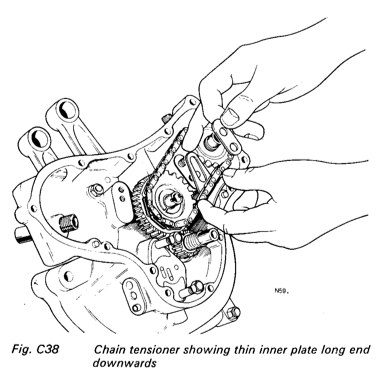

7) Assemble the chain tensioner.

NOTE: The chain tensioner clamping plates are different - the inner is thinner and the long end goes DOWN. The outer is mounted long end UP.

8) Fit the chain tensioner, fan disc washers and nuts moving the tensioner to give a maximum of 3/16" up and down movement at the tightest point. Double check you've found the tightest point.

NOTE: You need to use a dummy timing cover to get this correct as the intermediate shaft will tend to move when you tension the chain. Additionally the intermediate shaft might also become loose in it's bore - which will then need to be repaired.

Lock up the tensioner nuts.

9) Fit the oil pump drive worm - its LEFT HANDED!

10) Fit the camshaft sprocket nut - RIGHT HAND thread.

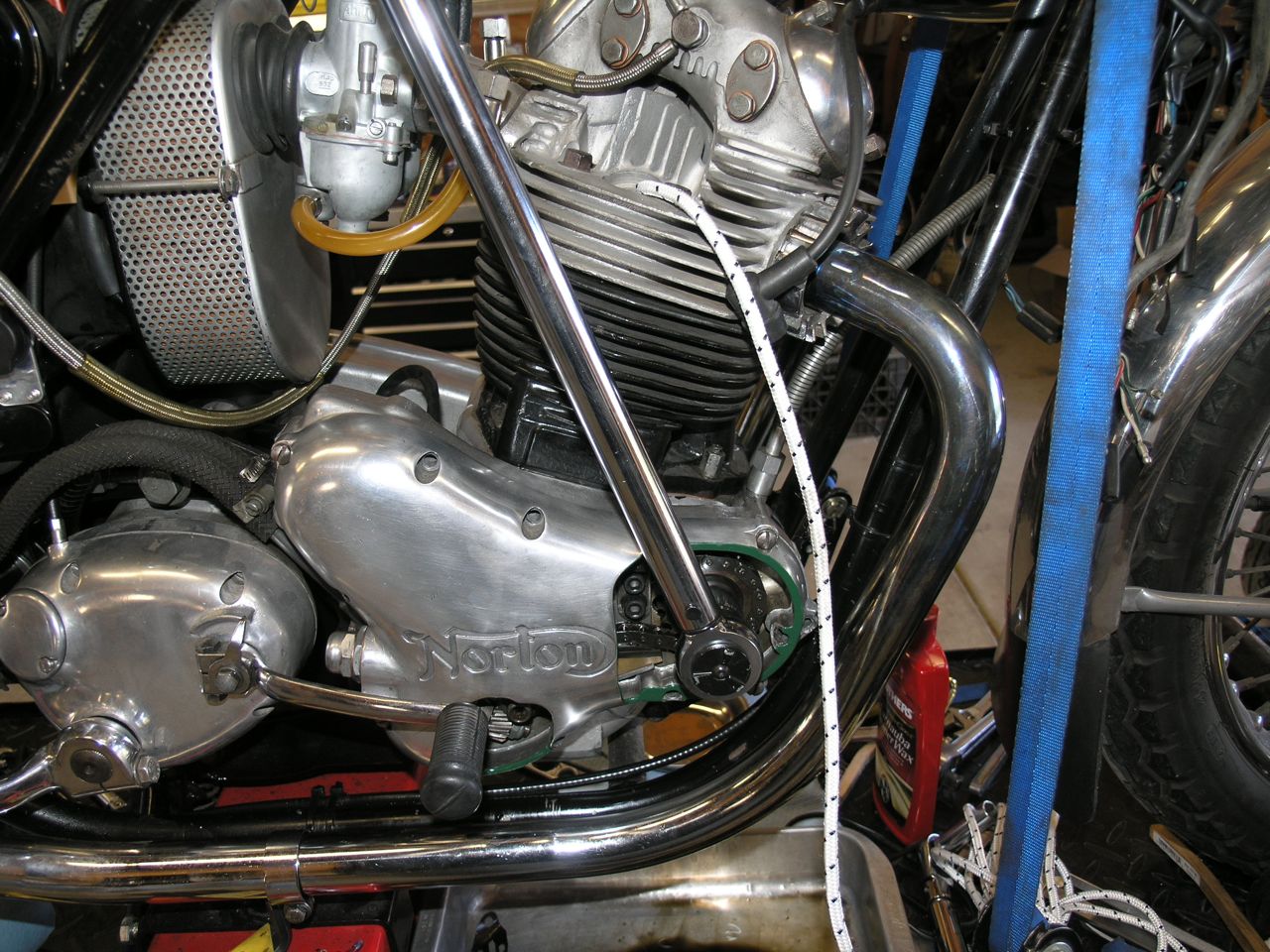

11) Tighten both nuts. If the engine is apart - you can lock up the crankshaft by using the deepest flywheel balance hole and a bar. If the engine is together, you can use the rear brake or place a length of rope into the spark plug hole near TDC (be careful not to interfere with the valves).

NOTE: DO NOT ever shock the camshaft nut - the cam is hardened and brittle. Shocking this nut by hitting a wrench with a hammer or using an impact wrench might crack the end right off. Use a nice steady pressure. You really should support the intermediate shaft when you tighten these nuts so that is not pulled out of alignment . I torqued the cam nut to 60 fl lbs. This picture shows the dummy timing cover I made from a junked one (really it was trashed - crash damage to the AAU area purchased on eBay for 10 bucks.) Also note the rope for a piston stop - works great.

If you've had the pump apart, you should prime it. Turn it by hand while you feed oil into the gears.

12) Fit the oil pump and secure the two nuts without washers to 10/12 ftlbs. I used some blue Loctite.

NOTE: Some folks replace these studs with bolts to effect a more secure mounting. I'm not sure how critical this is.

13) Fit a NEW conical rubber seal (Part No NMT272) on the pump outlet stub. Don't add any shims - even if there were some there when you tore it down.

14) After the oil pump is mounted, double check the driving gear nut.